A camshaft position sensor on a BMW is a sensor that reads the position

of the camshaft in relation to the engines timing and fuel delivery. There are

two camshaft position sensors, one inlet and one exhaust, but the one that

fails most commonly is the inlet sensor. If a camshaft sensor goes bad, it can

result in erratic idling, as well as stalling. Fortunately, it is a relatively

easy part to replace for even the relatively inexperienced home mechanic.

1.The sensor is located on the left side of the oil filter. Remove the air

filter and air filter box.

2.Disconnect the wiring harness to the mass air flow sensor and the air

box temperature sensor.

3.Remove the tube that leads to the idle control valve.

4.Unscrew the 6-mm nut with a socket that holds the hose clamp that

downstream of the mass airflow sensor. You should now be able to see the

camshaft position sensor.

5.Remove the air intake silencer with a 10-mm socket.

6.Using a 5-mm Allen key, remove the nut that holds the camshaft sensor in

place. Remove the engine cover and disconnect the sensor electrical connection

at the top of the motor. Clearance around the dipstick is tight, but it is

possible to remove the connector.

7.Install the new camshaft sensor with an oiled O-ring. Ensure that the

sensor seals properly, and then reassemble everything in the order of removal.

Professional OEM Factory from China, focus on automotive tools and bearing puller,hand tools,Accepted customized and offer professional solution and appliactions for car mechanic and extractor bearings. Detail click nbdntools.com to learn more

Wednesday 27 May 2015

Tuesday 19 May 2015

How to Replace a Ford Explorer Rear Hub Bearing(Wheel Bearing)

This information is from the Ford Service Manual for a 2002 Ford Explorer, however it can be used for all 2002-2005 Ford Explorer, Mercury Mountaineer and Mercury Mariner vehicles.

Steps

1.Remove the wheel and tire assembly.

Have an assistant press the brake pedal to keep the axle from turning.

2.Remove the nut and washer and discard the nut. A new nut is recommended and usually comes with the bearing.

3.Remove the brake caliper by removing the bolts from the back side of the caliper bracket.

Hold the caliper out of the way but do not allow it to hang by the

brake hose. Hanging the caliper from the brake hose can cause internal

damage to the brake hose. The brake caliper will slide off of the hub

once the caliper is removed.

- Do not damage the boot while separating the toe link from the knuckle.

4.Remove the nut and bolt and separate the toe link from the wheel knuckle and discard the nut.

5.Remove the nut and bolt and separate the upper ball joint from the wheel knuckle and discard the nut.

- Do not use a hammer to separate the outboard CV joint from the hub. Damage to the threads and internal CV joint components may result.

6.Make sure the axle is free from the hub. The axle

basically floats inside the hub and you can usually push slightly on the

end of the axle to make sure it is disengaged from the hub.

7.Remove the nut and bolt and the wheel knuckle, hub and bearing as an assembly.

8. Take the entire assembly and a new hub repair kit to a machine shop and let them do the actual press work.

Doing this yourself is not recommended unless you have access to a

heavy duty press with all of the proper adapters. Improper equipment or

experience can cause damage to the new bearing, knuckle assembly, and

could also cause bodily harm.

9.Install by reversing the removal procedure.

Monday 11 May 2015

How to Use a Hand Impact Driver

Hand impact drivers are fantastically simple tools. The first time you

see one, you will wonder how it could possibly work---but work they do, and

amazingly well. There's no other tool that handles the job these tools were

intended for. There's a great deal of control with a hand impact driver, unlike

a power impact tool. If you can hold the tool and swing a hammer, you can use

this very affordable and indispensable tool.

7.Tighten a bolt or

screw in the same manner, and by applying a turning force in the opposite

direction

1.Install the bit adapter and bit or the

appropriate socket on the tool.

2.Grasp the tool firmly in your left hand

(if you're right-handed).

3.Engage the stuck screw or bolt.

4.Apply downward pressure, while at the

same time attempting to turn the impact driver in the direction you want the

screw to turn. This is generally counterclockwise to loosen, clockwise to

tighten.

5.Strike the top of the impact driver with

a hammer. Wear heavy gloves to minimize injury if you accidentally hit your

hand with the hammer.

6.Continue striking the tool while applying

pressure and turning force until the bolt is loosened enough to use a faster

tool, such as a socket and ratchet wrench.

Sunday 10 May 2015

How to Use a Bearing Separator

A bearing separator comes in handy when replacing the steering pump,

rebuilding your alternator or performing any other similar repair job in your

car or any other piece of equipment. A bearing separator is very effective in

removing bearings, pulleys, gears and bushes fitted too close to the housing or

other components, leaving regular jaw pullers no chance to do their job. Save

on repair costs and finish your repair job in your garage using a few tools

along with a bearing separator.

1.Unscrew the two large bolts on each side of the bearing

separator -- holding the separator split plate together -- just enough so the part

you want to remove fits right in the middle of the separator plate. Use a

wrench, if necessary.

2.Place the bearing separator over and behind the bearing, gear or

pulley you want to remove, with each half of the separator plate on each side.

If the separator plate does not fit right behind the part you want to pull

because the space is too tight, line the center, tapered edge of the split

plate as close to the bottom of the part as possible.

3.Tighten the two bearing-separator bolts with a wrench so the separator

plates fit tight behind, or close to the bottom of, the part you want to

remove. You want the plates to be tight enough around the part to get a good

grip, but not too tight to prevent damage to any component.

the part as possible.

4.Screw the twin, steel beam over the bearing separator using a wrench.

The twin beam comes with your bearing separator kit and has two large bolts on

each side and another large bolt on the center of the beam. You want to screw

the two side bolts on the beam to the two threaded holes provided on the

separator plate.

5.Begin to screw the beam's center screw by

hand until the race on the tip of this screw rests on the shaft where the

bearing, gear or pulley you want to remove is mounted on.

6.Start to tighten the beam's center screw with a wrench, making sure

the bearing separator plates are holding tight on the part you want to remove.

As you tighten the beam's center screw, the bearing separator plates will begin

to pull on the part you want to remove.

7.Keep tightening the beam's center screw until you release the bearing,

gear or pulley off the mounting center shaft. Or, if you prefer, you can remove

the bearing separator once there is enough room behind the part you want to

remove for the puller legs of a jaw puller to finish removing the part.

Monday 4 May 2015

How to Rebuild an Engine

Rebuilding an engine is a big job, but planning smartly for a successful rebuild project can help eliminate the possibility of costly mistakes, saving you time, energy, and frustration. Learn to remove and reinstall your engine block, as well as how to disassemble and inspect the components to restore your engine to like new condition, or to customize it for maximum performance. See Step 1 for more information.

Part 1 of 5: Removing the Engine

1.Thoroughly clean the engine before beginning if possible. Accumulated dirt, grime, and grease will make removing bolts and disconnecting components a messy job.

2.Position the vehicle near your hoist. You'll need to be able to work on an even and well-lit surface, with enough room to position your hoist and maneuver around. If you've got a big enough garage, all the better.

It's a good idea to take close-up pictures of as many components in the engine as possible, from different angles. As you get to working, these can be invaluable. You might even print them out and label them for a reference.

3.Organize your work area before you begin. Having tubs to hold bolts, clamps, and fasteners to sort these, a workbench or table to lay out tools on, and a parts soaking and cleaning bucket will make handling these items easier.

4.Remove the hood. Mark the hinge bolts so you'll be able to find them later. Loosening them carefully, have a helper assist as you slide it off and store it while you complete the job. Note that some hoods have electrical connections for an underhood courtesy light or for headlamps, signal lights, and fog lights that are mounted on it. These should also be disconnected.

5.Start disconnecting the external engine components. It's important to disconnect the ground cable on the battery before you do anything else, then start draining the coolant and radiator hoses to do the job safely. Be very careful not to damage the metal clamps, which are more difficult to replace than the rubber hoses, which you might have to cut or break.

Remove the radiator and fan shroud (if applicable). Be gentle with it, the aluminum cells are delicate, and can easily be damaged.

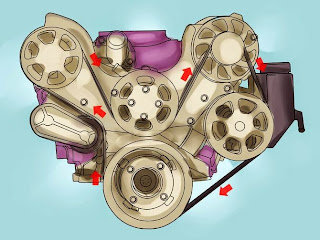

Next, loosen the alternator, the tension assembly, cooling fan(s), and belts. Disconnect the intake air supply and the fuel lines. Some vehicles have a fuel system which is pressurized even when the engine is not running, so be prepared to drain the fuel and relieve the pressure before disconnecting them. When you unbolt the power steering pump and air conditioning compressor, do it without disconnecting the hoses to save yourself some time in reassembly.

It's a good idea to make drawings and take close photos, as well as labeling the hoses and wires with tape and marker. Do not depend on memory. Some wires and hoses will only plug into place in one way, but some are not obvious. You'll likely still need a chart, diagram/drawing, and pictures to ease the reassembly process.

6.Remove all electric connections to the motor. You can leave the spark plug wires for later, but start disconnecting the exhaust manifold and unbolt all visible electric connections to the transmission in preparation of disconnecting the transmission.

7.Remove the bolts that attach the transmission's bell housing to the engine. Jack up the car and put it on jack stands, then support the transmission from underneath with other jack stands. It's very important to use jack stands, or some other support under the transmission before you disconnect the bolts. Once you loosen them, there won't be anything supporting the transmission and it will fall unless it's being held up by something. For vehicles with an intermediate cross member, this won't be an issue.

In most cases, the transmission itself doesn't need to be removed from the vehicle, as long as it can be safely supported when the engine is removed.

8.Use the hoist to remove the engine. Connect the hoist to the lifting points on the cylinder heads, or the biggest bolts near the top of the engine and adjust the leveler slowly to start lifting the front.

Be extremely careful. Swing motor free of car to avoid hitting the car and lower the engine onto your work surface, or the ground to start disassembly and inspection.

Part 2 of 5: Inspecting and Disassembling the Engine Block

1.Get the shop manual for your vehicle. No overview could offer all the specifics necessary to rebuild every kind of engine, making it essential that you defer to the manufacturer's instructions for every make and model. Get a hold of one, read it, and keep it on hand.

Even if you've got an older model, shop manuals are on eBay all the time for relatively cheap, and are often available at the public library for free. If you're going to invest in the project, it's absolutely essential that you get the shop manual so that you can learn the proper specs and particularities of the engine you're dealing with.

2.Perform a visual inspection of engine. Inspect fluid sweeping out of the many plugs, sending unit connections, and joints between components. Inspect the Harmonic balancer for signs that the isolation rubber is cracking, which may suggest it needs replaced. Check for any signs of overheating, cracking and scorching on the block. Also check for any excessive gasket sealer left behind from previous work.

Also, check the ID and casting numbers to ensure that the engine you think you are working on is actually the engine you are working on. Engine swaps are not uncommon and each engine has different specifications.

3.Inspect the external components on the engine. Inspect the distributor for signs of looseness by putting some pressure on it. Inspect the alternator belt for signs of wear by spinning the pulley and listening for any unusual noise. Inspect the clutch assembly for wear.

4.Remove the exhaust manifold if it was not removed earlier to facilitate removing the engine the engine compartment. The exhaust manifold bolts or studs may be very corroded, take care to break them loose without damaging them. Using special lubricants for this may help, and extremely stubborn bolts may require heat to loosen.

5.Begin disassembling the rest of the engine. Start by removing the oil pan and the valve covers, then the cylinder heads. Be sure to protect the lifter rods when lifting the cylinder head(s), if they are bent or damaged, they will need to be replaced.

6.Check the cylinder bores. You may want to use a micrometer to determine the bore diameter, very worn cylinders may be too far gone to allow a successful rebuild. If you know the engine hasn't been rebuilt previously, you can get a good idea of the wear to the cylinder walls by looking at the cylinder ridge. This is the point where the piston rings top out, the surface below the ridge is worn down the contact of the cylinder rings as they travel up and down, the tops isn't worn, so it indicates the original bore diameter. Generally, if the wear is less than 20/1000 of an inch, the original pistons can be reused, over 20/1000s will require the engine to be bored and oversized pistons to be used.

7.Remove the ridge on the cylinders near the top of the bore with a cylinder reamer (rimmer). The ridge is the point where metal of the cylinder did not wear because the rings do not rise that high in the bore. The cylinder wear should be below this point, but the ridge must be reamed out before removal to allow pistons to be removed and without damage and to make re-installation of the pistons with new rings possible.

8.Remove piston and rod assemblies. After removing the rod caps from the rods, place rod journal protectors (protective covers) on the rod ends and protect bolts to prevent them from striking, scraping and scoring the engine block or from bolt threads being damaged during removal and handling. Rubber fuel hose can be cut to slip over the bolt threads in this case. Once removed replace the same rod cap back on the matching rod, keep them as numbered paired/matched sets. Keep the parts marked or in order for return to the same cylinder from which they were removed. This to assure balance and fit; and consistent "break" in.

9.Remove and inspect the crankshaft. Once removed store in a safe place, preferably use crank mounting plates so that you can accurately measure the crankshaft. Keep old main bearings in order, inspect them for wear and excess dirt. With the crank removed and stored correctly place the main caps back on the engine block and torque to specification.

Remove the camshaft, balancer shafts, and auxiliary drives. Pay attention to end play shims and spacers, keep these organized you will need to put these back in the correct order. Remove the cam bearings, paying attention to their position.

10.Perform a visual inspection of the crankshaft. Inspect for cracks and any signs of overheating. Measure different crankshaft dimensions. These dimensions include journal diameter, out of round, taper, and run out. Compare this to the dimensions listed in the shop manual.

If the crank is out of spec, mark it for identification and have it sent to a machine shop you trust with the necessary machinery for resurfacing or turning to return the bearing journals to round. If the crank is turned, make a note of the cut, bearings will need to be ordered to match the new journal diameter.

Once the machine shop has reground the crank, you can use a rifle brush to remove the excess debris from the oil passages. Then measure the crankshaft again so that you can replace the bearings to get the crank to bearing clearance within specification.

11.Finish disassembly. Remove the core plugs, brackets, guide pins, and everything else still attached to the outside of the engine block. Perform a visual inspection of the engine block itself for any cracks.

If you want to, it might be a good idea to Magnaflux the engine block to look for leaks. Magnaflux should only be used to find leaks on cast iron. Use dye penetrant to find cracks on aluminum blocks. Most machine shops will perform these inspections, and may also pressure test engine blocks and cylinder heads. You may have them hot tank the engine block and cylinder head to clean it while you are at it.

12.Measure the specs. It's probably best to have this done at the machine shop, but if you've got the necessary tools yourself, you can use a straight edge and a set of feeler gauges to check the deck surface for flatness. Measure the both diagonally and horizontally. If the deck surface exceeds the specification for flatness resurface the block. Use caution when resurfacing not to remove too much material. If too much material is removed you risk having the pistons collide with valves.

Using a dial bore gauge measure each cylinder bore’s taper and for out of round. Inspect each cylinder for discoloration and washboard. Use a rigid stone hone to identify washboard. Check alignment and out of round of the main bearing bores with a dial bore gauge.

Part 3 of 5: Disassembling and Inspecting the Cylinder Head

1.Use a valve spring compressor to compress the valve springs. With the spring compressed, remove the valve keepers and slowly release the valve spring out of compression. Once you can remove the compression tool, remove the valve springs and shims. Keep these components in order.

2.Remove the valve from the head. Try not to force it out, which can scratch the guides. For each valve, you need to remove any carbon buildup or dirt from valves and valve head. If possible have the head shot peened or glass beaded at the machine shop, or use Magnaflux or dye penetrant to find any cracks.

3.Check each valve head for flatness. Note any flatness which is out of specification so that it can be corrected at the machine shop after inspection. Inspect the guides for excess wear using a dial indicator and check for recession of the valve seats. It's also essential to check for:

Worn valve stems. Use a micrometer and replace any valves whose stems exceed specification.

Worn keeper grooves. Replace any worn keepers.

Thin margins. Margins should be thinner on intake valves than exhaust valves. Replace valves with excessively thin margins.

Length, tension, and squareness. Replace any springs which are worn beyond specification.

4.Recondition the worn valve guides. Replace the recessed valve seats and reface all valves which are not going to be replaced. Machine the valve seats. Lubricate the valve stems with engine oil. Install valve seals.

The valve seals come in 3 different types: band, umbrella, or PC type. Pay attention to the order of assembly. Assemble valve heads. Check for leaks using either a liquid test or a vacuum test, or have them perform this at the machine shop.

Part 4 of 5: Reassembling the Block

1.If the block was machined, recheck all the dimensions. Machine shops do make mistakes, but its your job to double-check their work. Check that the oil channels and openings of the oiling system in the block are free and clear of all metal shavings, dirt and debris.

Wash block using hot soapy water, then blow dry thoroughly to remove any moisture from the engine. Blow out all bolt holes using compressed air to remove any debris prior to installing fasteners.

2.Oil the components thoroughly. Install oil gallery plugs and core plugs using hardening sealer. Never use silicone sealer in these areas, which can dissolve and also could form into rubbery debris in the oiling system.

Prepare to lubricate main bearings by cleaning and drying the main bearing bores and the backs of the bearings. Lubricate the inside of all the main bearings and the lip on rear main seal with the recommended OEM oil/grease. Then install main bearings and rear main seal, keeping sure install in the correct position.

3.Install crankshaft and main caps. Grease the camshaft bearings with high pressure grease, then install the camshaft. Since the caps are sensitive to position and direction, snug the caps and then torque them onto the block from the center moving out.

Rotate crank to see if it binds up. If the crank rotates smoothly, then next check the end play.

4.Install the timing chain or belt to specification. Be sure to align the timing marks correctly during reassembly and degree the cam.

To degree the cam and set the timing, aligning the timing marks at Top Dead Center and set the degree wheel correctly on the cam, with the crankshaft/piston timing and proper valve timing sequences for intake, compression, power, and exhaust strokes of the engine.

5.Install new pistons, rings, gaskets, and seals. Check piston ring end gaps for OEM clearances. You may need oversize rings. If the rings are too small in diameter they'll have excessive end gap, but if they're too large then they'll be too tight and can bind, perhaps even breaking when the engine heats up.

When you're installing, you should stagger the ring end gaps on the pistons. The tiny gap at the end of each ring are turned 180 degrees apart around the piston, compared to the next ring, reducing what's sometimes called "blow-by". Be sure the oil expander ring is fitted/butted properly.

6.Install the piston and rod assemblies. Use rod journal protectors and lubricate the rod inserts, then install and torque rod caps. While you are installing the rods, first barely snug and then torque these gradually in 3 stages to ensure that they all seat evenly and properly.

Continue rotating the crankshaft after installing each piston and torquing the rod caps to make sure it still rotates freely. If gets too hard to turn, you'll know the last piston in that cylinder or the rod inserts are binding--insert halves must snug up without the end of one insert slipping under the other half. Spin test crank after each bearing is installed.

7.Install head gasket. The gasket may be directional, so be sure to install in the correct direction. Remember to put in the head to block bolt or the OHC belt will never run true and then shred. Only use "gasket cement" if the manufacturer instructs you to.

8.Install new valve heads. Lube the bolt threads and washers with Original Equipment Manufacturer (OEM) lubricant or sealer, then torque the bolts down in 3 stages using the OEM specified pattern. Pay close attention to both the length and the location of the bolts.

9.Install a new valve train. Be sure to lubricate the parts as you install them and adjust the valves as necessary. Use a minimum of up/down motion, and then torque using 3/4 turns.

Part 5 of 5: Reinstalling the Engine

1.Complete other projects which might be necessary in the rebuild. If you're doing a complete overhaul, it's likely you'll want to do other jobs at the same time while you've got the chance. Likewise, it's usually inadvisable to hook up your freshly-rebuilt engine to a transmission with 200,000 miles (320,000 km) on it. You might want to:

Install a transmission

Replace the air conditioner

Change out the radiator

Get a new starter

2.Prep the engine. Fill the new oil filter with motor oil before installing, and with break-in oil recommended by the engine rebuilder. Prime the oiling system by manually operating the oil pump. Fill the cooling system with a 50/50 mixture of new antifreeze coolant and distilled water.You'll also probably need to install:

OEM spark plugs

new distributor cap, rotor and spark plug wires

new air filter, fuel filter, crankcase filter and PCV valve

3.Lower the engine with the hoist. It's important to keep the engine level while lowering it into place. Use caution, and help. Fasten it to the mounting brackets and reconnect all the hoses, pipes, and wires, having ensured that they're all compatible with any new parts you've installed. Reinstall the radiator and hood, being sure to keep anything meltable clear of the exhaust headers.

4.Go through a careful initial start-up. Set the emergency brake and block up the wheels before you start the ignition.Turn the ignition. If the engine doesn't start, check the fuel delivery system.

Make sure to monitor the oil pressure gauge and the temp gauge. If you notice full oil pressure, cut the engine immediately and check for fluid leaks. If you notice anything unusual, stop the engine immediately.

5.Break it in. After you get the engine running reliably, rev it to 2000 rpm to thin out any oil on the camshaft. You'll want to run the engine at various speeds between 1800 and 2500 rpm for at least 20 minutes.

Pull the radiator cap to check for adequate flow or leaks before it gets too hot. Check that the battery is charging.

6.Change the oil and filter after your first 100 miles (160 km). It's important to ease the engine into it's life, and it's common to change the oil after about 100 or 200 miles (160 or 320 km) initially, then every thousand miles for at least the first three months of use.

Subscribe to:

Posts (Atom)