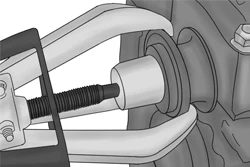

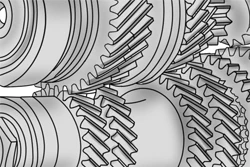

A gear puller is a tool that is specially designed to pull gears from shafts. There are many different styles of gear puller designs, all intended to fulfill a particular purpose. Some designs use jaws to grip the gear while others use bolts to attach the it directly to the gear. One thing the styles have in common is that all types of pullers use a threaded rod to press against the gear's shaft and apply pressure until it comes loose. No matter which design is utilized, the proper puller makes the removal of a gear an easier task.

Often used on small gears in very tight quarters, the two-jaw puller is the puller of choice. Having two arms or jaws that grasp the gear as the threaded rod comes in contact with the gear's mounting shaft, the rod is tightened, which applies pressure to the two arms or jaws as they pull the gear from the shaft. Often, in the case of a stubborn gear, the pressure must be applied to the gear by tightening the puller and then leaving it to sit under the pressure for a few minutes. Gradually tightening the gear puller will result in the release and removal of the gear.

Perhaps the easiest of all of the jaw type pullersis the three-jaw gear puller. By using three jaws, the puller is better equipped to apply even pulling pressure around the gear as the threaded rod is tightened against the gear's shaft. While best used on larger gears in open areas with easy access, this type of gear puller can also need the occasional aid in removing a very tight gear. In the instance that the puller is unable to pull the gear from its shaft, the threaded rod can be tightened and then hit on the head with a hammer. This will usually loosen the tightest gears with one attempt.

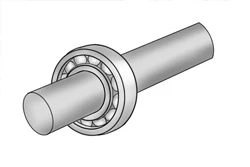

Gear pullers are tools used to detach gears from their shafts.

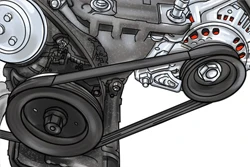

The bolt on a gear puller is used on gears such as an automobile engine harmonic balancer and even steering wheels where the gear has threaded bolt holes around the perimeter. The puller is attached to the gear with bolts and the threaded center rod is tightened against the gear's shaft. As pressure is applied the gear will pop loose from its shaft and can be easily removed. When using any gear puller, it is important to keep the puller as close to level with the gear as possible to assure a straight pull.